September 8, 2020 11:00 am

by Michael P. Culmo, P.E., Chief Bridge Engineer, CHA Consulting, Inc.

The 2020 in-depth web training features the design and construction of common ABC technologies using the AASHTO LRFD Guide Specifications for Accelerated Bridge Construction, 1st Edition, 2018. The web training is four hours in length and consists of six modules, each a 30-minute presentation followed by a 10-minute Q&A session. The first five modules cover the design of precast full-depth deck panels, adjacent modular decked beams, precast abutment and pier elements, self-propelled modular transporter (SPMT) bridge systems, and lateral slide bridge systems. Several worked examples are presented to give participants experience with the actual design for ABC. The workshop concludes with an in-depth look at the development of construction specifications for ABC projects.

Michael P. Culmo, P.E.

Chief Bridge Engineer

CHA Consulting, Inc.

Office: 860-290-4100

Email: MCulmo@chacompanies.com

Mike is a Bridge Engineer with over 36 years of experience in the design of steel, concrete, prestressed concrete and timber bridges. He has special expertise in the field of accelerated bridge construction technologies and constructability engineering. Mike is the principal author of numerous publications in the field of ABC, including the 2018 AASHTO LRFD Guide Specifications for Accelerated Bridge Construction. He is a licensed professional engineer.

Reference Documents:

01 - Agenda

02 - Presentation Handout (2 slides/page)

03 - FHWA Design Example: 2-Span Steel Girder Including Deck

04 - FHWA Design Example: 2-Span Prestressed Concrete Girder

05 - NCHRP 12-98: Tolerance Guide

06 - NCHRP 12-98: Bridge System Dynamic Guide

07 - PCI State-of-the-Art Report on Full-Depth Precast Concrete Bridge Deck Panels

08 - PCI NE Recommended Guide Details for FDDP

09 - PCI NE NEXT Beam Details

10 - PCI NE Recommended Guide Details for Substructures

11 - PCI NE Camber and Profile Management Guide

12 - PCI NE Guidelines for Resolution of Non-Conformances in Precast Concrete Bridge Elements

Module 1: Precast Concrete Full-Depth Deck Panels

Description: Precast concrete full-depth deck panels represent a common ABC technology. The AASHTO Guide Specifications for ABC cover all aspects of deck panel design. This module includes a fully worked design example for a precast concrete full-depth deck panel bridge. The example covers two different methods of connecting panels. The first method is cast-in-place concrete closure joints reinforced with hooked bars. The second method is reinforced closure joints filled with ultra-high-performance concrete (UHPC). The module concludes with typical calculations for handling panels.

- Design Considerations

- Example

- Closure Joint Options

- Example: Closure Joint Connection with Concrete

- Example: Closure Joint Connection with UHPC

- Lifting and Handling

- Example

1. Precast concrete full-depth deck panels – longitudinal configuration – in MassDOT’s Commonwealth Avenue Bridge

Module 2: Adjacent Modular Decked Beams

Description: Adjacent modular decked beams provide a means to replace or install superstructures very quickly. A feature common to all modular decked beams is that the deck is integral to the supporting beams. This eliminates a difficult process of making a concrete deck composite. This module covers the design and detailing of adjacent modular decked beams, including both steel and prestressed concrete options. Topics covered include the design requirements for the beams, management of profile geometry, the design of deck-level closure joints, designing for live load continuity, and span-by-span construction with link slabs.

- Types of Adjacent Decked Beams

- Steel

- Prestressed (NEXT Beams)

- Design Requirements

- Live Load Distribution

- Deck Level Connections

- Simple for DL Continuous for LL

- Link Slabs

2. Modular decked beams with steel girders – in MassDOT’s FAST 14 project

Module 3: Prefabricated Substructures

Description: Prefabricated substructure elements are becoming more common in the ABC world. It is feasible to prefabricate all types of substructure elements. This module covers the design of common prefabricated substructure elements, including integral abutments and cantilever abutments. The module also includes the design of open-frame pier bents.

- Abutment Examples

- Precast Integral Abutment

- Precast Cantilever Abutment

- Piers Examples

- Grouted Coupler Connection

- Socket Connection

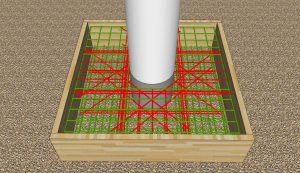

3. Socket connection – precast column with cast-in-place footing

Module 4: Bridge Systems with Self-Propelled Modular Transporters (SPMTs)

Description: Installation of bridge systems using Self-Propelled Modular Transporters (SPMTs) was one of the early methods of ABC system moves used in the United States. These machines can be used to move entire bridge superstructures from an offsite staging yard to the bridge site, resulting in very fast construction that can be of significant benefit for high traffic volume locations. They can also be used to remove existing structures. This module covers the design of bridge systems installed with SPMTs. The roles and responsibilities of the designer and the contractor are outlined. The design of the bridge to accommodate the move is also covered, including a study of the dynamic effects imparted on the bridge and falsework during the move.

- Designer/Contractor Responsibilities

- Design of the Bridge

- Preliminary Layout

- Dynamics

4. SPMT bridge system – Utah DOT

Module 5: Bridge Systems with Lateral Slides

Description: Lateral slide bridge systems have recently become quite popular in the United States. They can be a low-risk option for bridge system moves and provide significant benefit for bridges over waterways or over low traffic volume locations. This module covers the design of bridge systems installed using the lateral slide technique. The roles and responsibilities of the designer and the contractor are outlined. The design and detailing requirements for the bridge are also covered.

- Designer/Contractor Responsibilities

- Preliminary Layout

- Recommended Details

- Example: RIDOT Bridge Project

5. Lateral slide system – Rhode Island DOT

Module 6: Construction Specifications

Description: The AASHTO Guide Specifications for ABC include significant guidance on construction specification development for ABC projects. This module covers construction specifications for all forms of ABC, including quality control, assembly planning, and specialized materials such as non-shrink grouts, high-early-strength concrete, and ultra-high-performance concrete (UHPC).

- Fabrication and Assembly Planning

- Quality Specifications

- Non-Conformance Repairs

- Materials Specifications

- Non-Shrink Grout

- High-Early-Strength Concrete

- UHPC

- Grouted Couplers

6. Confined shrinkage test set-up