August 23, 2018 1:00 pm

Amber Blanchard, P.E., State Bridge Planning and Hydraulics Engineer, Minnesota Department of Transportation; Steve Kordosky, P.E., Hastings Bridge Project Manager, Minnesota Department of Transportation; and Vincent Gastoni, P.E., Principal Bridge Engineer, Parsons

Webinar Documents:

Use of SPMTs, Barges, and Strand Jacks to Build the Hastings, MN Bridge - pdf of presentation

Q&A Session - pdf

News - August 23, 2018 - pdf of presentation

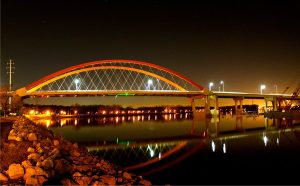

Description: The new Hastings, Minnesota Bridge is a 21st century landmark with a main span that boasts the longest free-standing tied-arch bridge in North America. This crossing of the Mississippi River is a highly redundant and robust structure with an expected 100-year service life. The main span was constructed on land on an adjacent staging area, moved onto barges with self-propelled modular transporters (SPMTs) and then guided downstream on a flotilla of barges. It was then positioned into its pre-lift location using a skid system and connected to hydraulic strand jacks that lifted the span vertically approximately 50 feet before making the final connection between the piers in September 2012. This $130-million-dollar project was delivered on an accelerated schedule using the competitive “design-build best value” contracting process. The presentation includes design and construction details and lessons learned.

Presentation Photos/Graphics: