Task1 – Literature Review

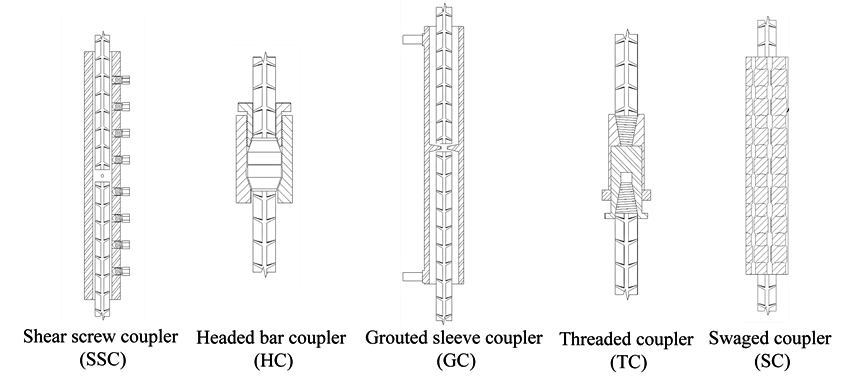

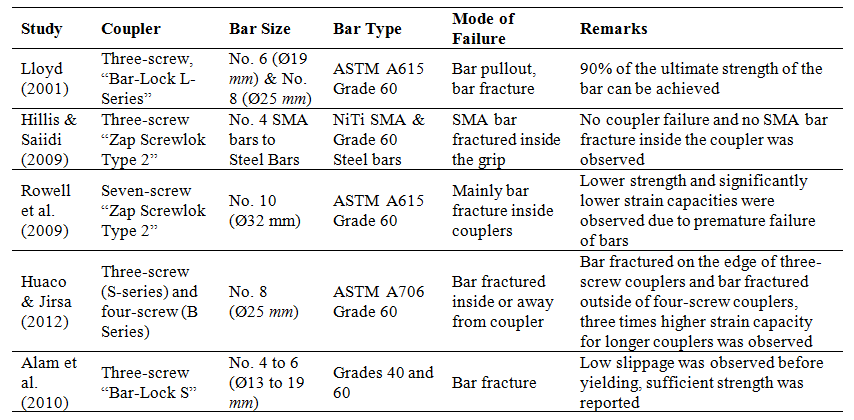

A state-of-the-art literature search was conducted to collect experimental data regarding the most common types of mechanical bar splices (Fig. 1). Test data included in this report was the performance of coupler itself under axial loading and the seismic performance of columns incorporating these coupler types in plastic hinge regions. The findings were summarized in various tables and figures. Table 1 and 2 present samples of the findings. The current code limitations for mechanical bar splices were also presented.

Figure 1. Mechanical Reinforcing Bar Couplers

Table 1. Summary of Studies on Shear Screw Couplers (Sample)

Table 2. Summary of Seismic Performance of Column Test Models with Grouted Sleeve Couplers (Sample)

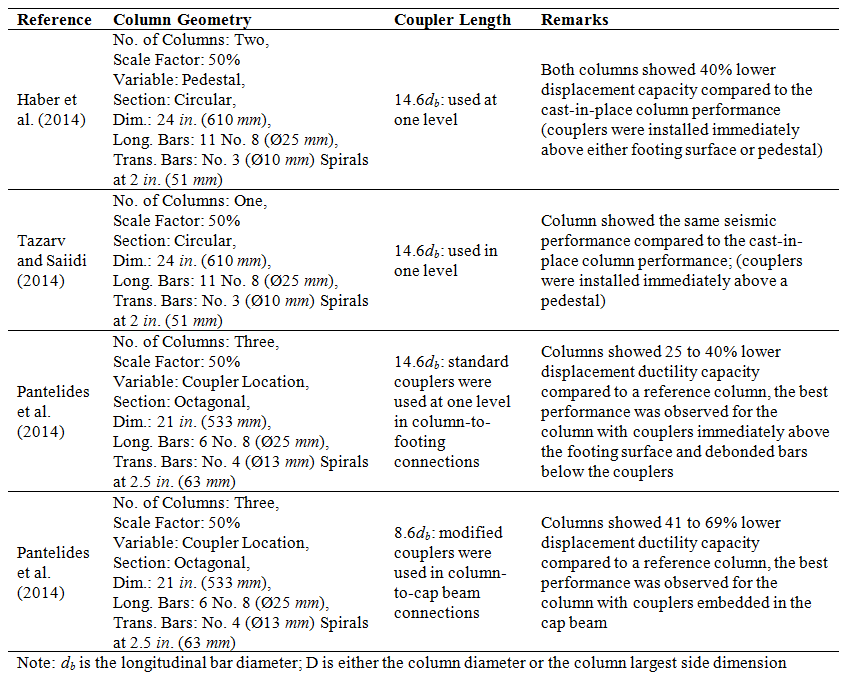

Task2 – Characteristic Seismic Performance of Different Couplers

Minimum requirements were established to evaluate performance of mechanical bar splices for seismic applications and to evaluate seismic performance of columns incorporating couplers in the plastic hinge region. It was found that coupler performance varies for different loading rates and even for the same type of coupler produced by different manufactures. Furthermore, location of the coupler is critical for large size couplers, and special detailing is needed to achieve large displacement capacities (Fig. 2). Satisfactory performance was usually observed for small size couplers in which their location had insignificant effect on the column seismic behavior.

Figure 2. Evaluation of Columns Incorporating Grouted Couplers

Task3 – Evaluating of constructability of different coupler types

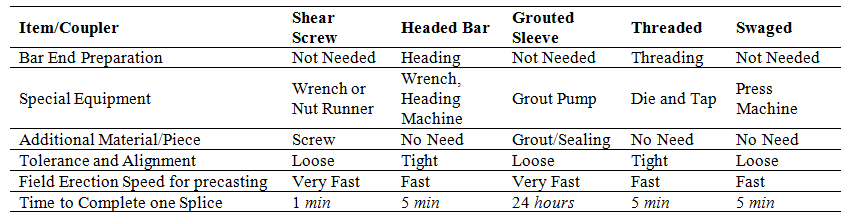

This chapter was dedicated to the constructability of different coupler types. Important considerations that are needed before field deployment were highlighted (Table 3), and speed of construction for each coupler type and speed of construction for precast columns incorporating couplers were evaluated. It was found that application of mechanical bar couplers at both ends of precast columns will shorten the construction time by approximately 60% for a three-column bent regardless of the type of the coupler.

Table 3. Constructability of Mechanical Bar Couplers

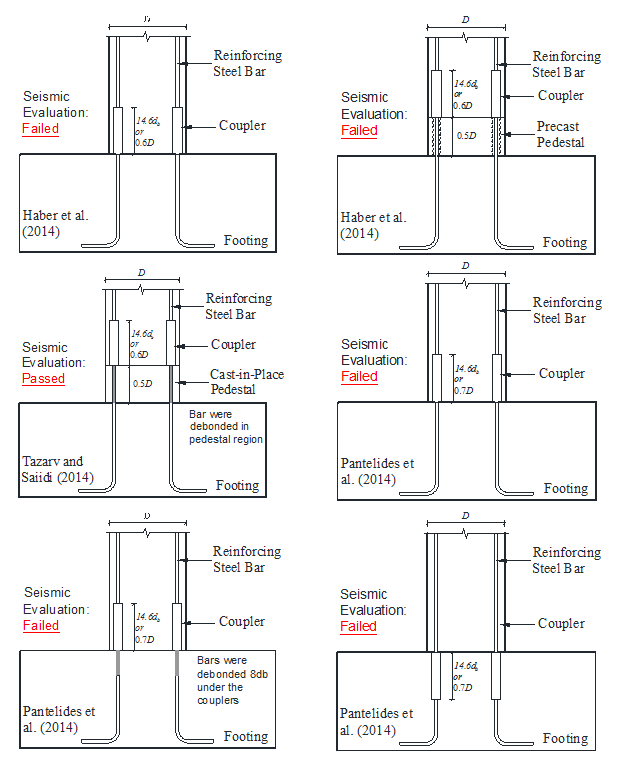

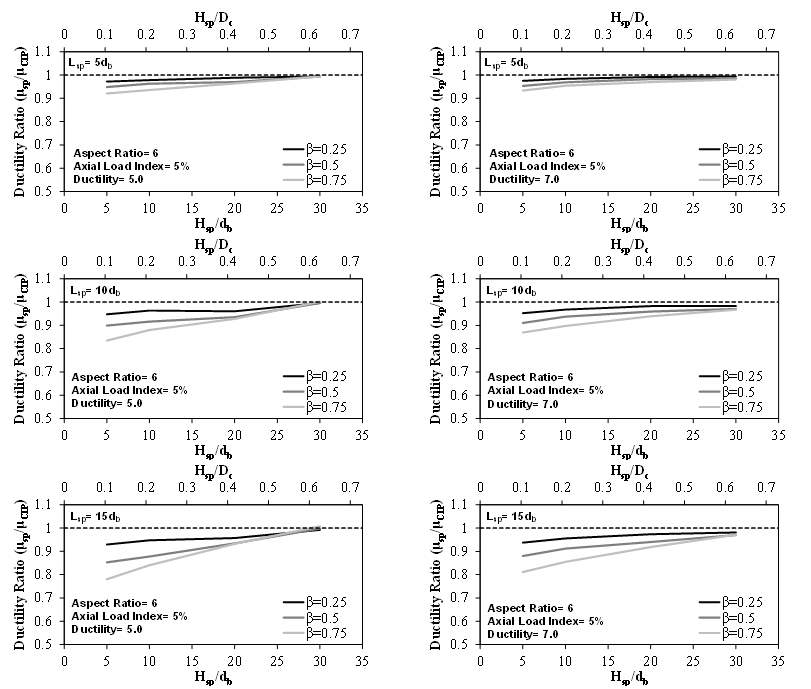

Task4 – Methods to estimate plastic hinge length and rotational capacity

A generic stress-strain model was developed for couplers then a comprehensive parametric study was performed to investigate coupler effects on the seismic performance of columns. The coupler length, coupler location, and rigidity of the coupler itself were found to be critical in which longer couplers, couplers closer to the adjoining member interface, and more rigid couplers reduces the column displacement ductility capacity. Figure 3 shows one sample of the findings in which the mechanically spliced column displacement ductility capacity normalized to its counterpart cast-in-place (no splice) column displacement ductility capacity was plotted versus coupler height from the column-footing interface.

Figure 3. Couplers Effects on Seismic Performance of Columns

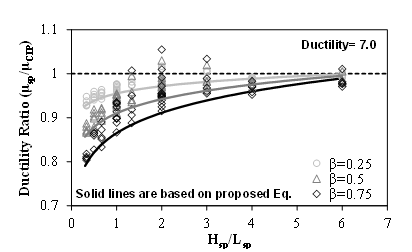

A design equation was developed in which the coupler adverse effect on the column ductility can be estimated knowing the size, location, and rigid length factor of the coupler (Fig. 4).

Figure 4. Proposed Design Equation Accounting for Coupler Effects