September 13, 2022 11:00 am

by Atorod Azizinamini, Ph.D., P.E., Professor, Department of Civil and Environmental Engineering, Florida International University (FIU); Royce Floyd, Ph.D., P.E., Associate Professor, Civil Engineering and Environmental Science, University of Oklahoma; David Garber, Ph.D., P.E., Interim Department Chair and Associate Professor, Department of Civil and Environmental Engineering, FIU; Benjamin A. Graybeal, Ph.D., P.E., Structural Engineer, Office of Infrastructure Research, Federal Highway Administration (FHWA); Kingsley Lau, Ph.D., Associate Professor, Department of Civil and Environmental Engineering, FIU; and John Stanton, Ph.D., P.E., Professor, Civil and Environmental Engineering, University of Washington

The 2022 In-Depth Web Training features the latest work related to Non-Proprietary Ultra-High Performance Concrete (UHPC). This training is four hours in length and consists of six modules, each a 30-minute presentation followed by a 10-minute Q&A session, with a 15-minute break between Module 3 and Module 4.

Brief History: In 2017, after an extensive discussion with State DOTs, feedback was the development of non-proprietary UHPC as a high priority. As a result, the ABC-UTC initiated a coordinated study that involved researchers from several of its partner universities. The goal of the initiative was to add value to the body of knowledge in the area of development of non-proprietary UHPC. More than four years of ABC-UTC research has resulted in the development of the ABC-UTC non-proprietary UHPC presented in this year’s In-Depth Web Training.

What Is Covered: The objectives of this In-Depth Web Training are to a) familiarize attendees with essential information needed to produce non-proprietary ABC-UTC UHPC, b) discuss mechanical properties of non-proprietary UHPC, c) discuss corrosion durability of UHPC, d) discuss advantages of using UHPC in design, e) discuss draft guidance and specifications developed by FHWA for design using UHPC, and f) introduce areas where UHPC can be used, such as retrofit/upgrade, connections, and 3D printing using UHPC.

Organizers and Presenters

Atorod Azizinamini, Ph.D., P.E.

Vasant H. Surti Professor of Civil Engineering;

Director, ABC-UTC;

Director, Moss School of Construction, Infrastructure and Sustainability;

Director, Preeminent Institute for Resilient and Sustainable Coastal Infrastructure (InteRaCt)

Florida International University

Office: 305-348-3821

Email: aazizina@fiu.edu

Atorod has led several major multi-disciplinary bridge engineering-related initiatives. He is a founder of two major transportation field organizations: the National Bridge Research Organization at the University of Nebraska-Lincoln and the Center for Accelerated Bridge Construction at Florida International University. He has developed several bridge engineering products and systems that are being used nationally and internationally. His current research interests include applications of UHPC solutions for repair, retrofit, and rehabilitation of bridge structures. He has published extensively and routinely gives keynote talks on bridge engineering topics in the U.S. and abroad. Additionally, Atorod has produced more than 50 graduate students at the M.S. and Ph.D. levels. He has also taught more than 40 short courses on the design and construction of superstructures and substructures to practicing bridge professionals.

Royce Floyd, Ph.D., P.E.

Associate Professor

University of Oklahoma

Office: 405-325-1010

Email: rfloyd@ou.edu

Royce is an Associate Professor in the School of Civil Engineering and Environmental Science at the University of Oklahoma in Norman, Oklahoma. His current research interests are focused broadly on behavior of UHPC, prestressed concrete structures, large-scale structural behavior, and innovative concrete materials. He has completed multiple projects focused on behavior of prestressed concrete structures and specialty concrete materials. He has published more than 40 technical journal articles in these areas. His research goals center on understanding and implementing innovative concrete materials to create longer lasting structures.

David Garber, Ph.D., P.E.

Associate Professor

ABC-UTC Director of Workforce Development

Florida International University

Phone: 305-348-4879

Email: dgarber@fiu.edu

David is an Associate Professor and Interim Chair in the Civil and Environmental Engineering Department at Florida International University (FIU) and Co-Director of the Accelerated Bridge Construction University Transportation Center (ABC-UTC) housed at FIU. He has led several research projects related to ABC and UHPC. Some relevant projects include a project developing a non-proprietary UHPC mixture design using locally available materials in south Florida, development of a new superstructure system for short-span bridges in Florida using UHPC for FDOT, and investigation of pocket and socket connections between precast piles and precast pile caps. He is also leading an FDOT-funded project looking at the bond between UHPC substrate and cast-in-place UHPC.

Benjamin A. Graybeal, Ph.D., P.E.

Structural Engineer

Office of Infrastructure Research

Federal Highway Administration (FHWA)

Phone: 202-493-3122

Email: Benjamin.Graybeal@dot.gov

Ben is the team leader for Bridge Engineering Research in the FHWA Office of Infrastructure Research. His expertise includes bridge engineering, structural concrete, concrete materials, and forensic investigations. He has a wealth of experience with UHPC, having been a leader in the UHPC community since FHWA began focusing on this topic in 2001. In Module 6, Ben delivers remarks focused on the effort to develop structural design guidance for UHPC.

Kingsley Lau, Ph.D.

Associate Professor

Florida International University

Phone: 305-348-6124

Email: kilau@fiu.edu

Kingsley joined the FIU CEE department in 2012 as Assistant Professor of Structural Engineering. Prior to coming to FIU, he served as Corrosion Research Scientist at the Florida Department of Transportation State Materials Office. Kingsley obtained his Ph.D. in Civil Engineering from the University of South Florida in 2010. He has established himself in the field of infrastructure materials durability, and his research interests include corrosion of engineering materials and durability of reinforced concrete and prestressed concrete. Kingsley is author or coauthor of over 100 technical documents in the field of corrosion.

John Stanton, Ph.D., P.E.

Professor

University of Washington

Phone: 206-543-6057

Email: stanton@uw.edu

John is the Thomas and Marylin Nielsen Professor of Civil Engineering at the University of Washington, where he specializes in Structural Engineering. Prior to becoming a professor, he worked in practice in England, France and Canada. His research interests are centered on the mechanics of prestressed and reinforced concrete, particularly with respect to seismic issues, but he has also conducted studies in other areas, such as bridge bearings (including authorship of most of the bearings provisions in the AASHTO LRFD Specifications) and is presently involved in studies of lateral stability of bridge girders, shear friction, and modeling of fiber-reinforced concretes such as UHPC. He is a member of several ACI committees, including 318P (prestressed and precast concrete), and has been a consultant on many large bridges in the U.S. and abroad.

Introduction

Module 1: Non-Proprietary/Open-Source Mix Design

by Royce Floyd, Ph.D., P.E., Associate Professor, Civil Engineering and Environmental Science, University of Oklahoma

Description: This module provides an introduction to UHPC and description of mix design development using the ABC-UTC mix design as an example. This discussion includes considerations for constituent material selection and mix proportioning methods.

- Module 1 presentation pdf

- Q&A pdf

Module 2: Material Properties

by David Garber, Ph.D., P.E., Interim Department Chair and Associate Professor, Department of Civil and Environmental Engineering, Florida International University

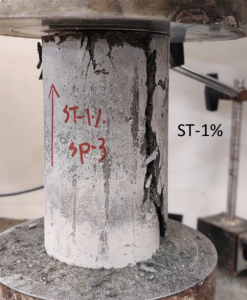

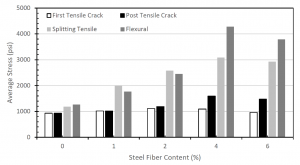

Description: Material and durability properties of the non-proprietary UHPC mixes examined by ABC-UTC researchers are discussed. This includes compressive strength, flexural strength, modulus of elasticity, creep, shrinkage, bond behavior with reinforcement and concrete, and includes effects of changing fiber type and content.

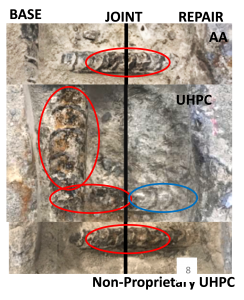

Module 3: Corrosion Durability

by Kingsley Lau, Ph.D., Associate Professor, Department of Civil and Environmental Engineering, Florida International University

Description: This module provides a description of factors influencing corrosion durability of reinforced concrete repaired with UHPC and the outcomes of research.

- Module 3 presentation pdf

- Q&A pdf

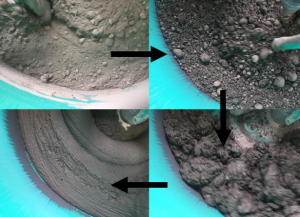

Figure 3-1. Accelerated corrosion test of UHPC link slab segment (Floyd et al., 2020)

Figure 3-1. Accelerated corrosion test of UHPC link slab segment (Floyd et al., 2020)

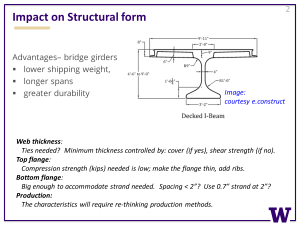

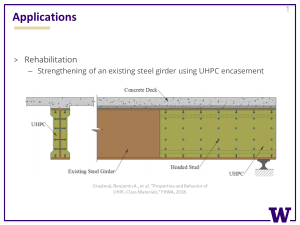

Module 4: Impact of Non-Proprietary UHPC Properties on Structural Design

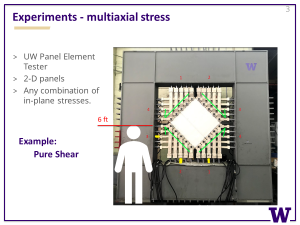

by John Stanton, Ph.D., P.E., Professor, Civil and Environmental Engineering, University of Washington

Description: UHPC is more expensive than conventional concrete, on the basis of material cost alone, and so it is not a direct substitute. However, many of its properties are greatly superior to those of conventional concrete. To take advantage of those properties in a cost-effective way requires selective use and careful planning. The module discusses some of the properties of UHPC that offer relative advantages, and links them to possible end uses. Many but not all of these are found in local regions of a structure where the special properties are urgently needed, but the size of the region is small, thereby allowing use of relatively small quantities of material.

- Module 4 presentation pdf

- Q&A pdf

Figure 4-1. Sample slides in Module 4

Module 5: UHPC Based ABC Solutions

by Atorod Azizinamini, Ph.D., P.E., Professor, Civil and Environmental Engineering Department, Florida International University

Description: This module provides an overview of major research conducted by the ABC-UTC on the use of UHPC in providing new and innovative solutions for bridge projects using ABC. These solutions could use non-proprietary UHPC. Application areas presented include repair of columns, timber piles, beams, and connections. The use of UHPC to replace formwork is also presented. The presentation briefly touches on trending topics that include 3D printing and shotcrete using UHPC.

Figure 5-1. Repair procedure: a) damaged part before repair, b) damaged part after sandblasting treatment, c) formwork for the repair plastering, d) casting UHPC, and e) damaged part after repair

Module 6: The Next Hurdle for UHPC – Structural Design Guidance and Specification Development

by Benjamin A. Graybeal, Ph.D., P.E., Structural Engineer, Office of Infrastructure Research, Federal Highway Administration (FHWA)

Description: As a new class of concrete that exhibits distinct, advantageous material properties, UHPC is proving valuable as innovators develop novel solutions to long-standing challenges. However, without formal structural design guidance, the widespread use of UHPC in infrastructure applications has been hampered. To address this hurdle, the US Federal Highway Administration’s Turner-Fairbank Highway Research Center has engaged in a multi-year effort to develop requisite knowledge, construct a rational framework, and draft the guidance necessary for UHPC structural design. The draft guidance parallels the AASHTO LRFD Bridge Design Specifications while proposing mechanical and structural behavior models that conservatively align with the behaviors expected from UHPC-class materials. The guidance, which is currently being considered for adoption by AASHTO’s structural concrete design committee, is founded upon basic principles of engineering mechanics, avoiding empiricism where possible and relying on parameters obtained from material-scale standardized tests to predict structural-scale responses. This module provides an overview of UHPC structural design concepts, focusing on foundational elements central to understanding and use.

- Module 6 presentation pdf

- Q&A pdf

- FHWA-HRT-22-065, Design and Construction of UHPC-Based Bridge Preservation and Repair Solutions, May 2022

- FHWA-HRT-22-087, Techniques to Inhibit Corrosion in Bridge Deck Reinforcement Prior to Overlay Installation, August 2022

Figure 6-1. Pretensioned UHPC bridge girder, optimized to engage the properties of this new class of concrete