Events in January 2024

-

Building Bridges at the Speed of Segmental Building Bridges at the Speed of Segmental

–

January 18, 2024Building Bridges at the Speed of Segmental

Matthew Adams, P.E., Senior Lead Bridge Engineer, Corven Engineering an H&H Company

Webinar Documents:

IBT-ABC Building Bridges at the Speed of Segmental - PDF of presentation slides

January 2024 News Slides - PDF of news slides

January Webinar - Questions and Answers - PDF of Questions and AnswersDescription:

The webinar will focus on segmental bridge construction methods and techniques that support accelerated bridge construction schedules. Topics covered will include segment pre-casting methods and operations, storage, handling, and transport as well as segmental erection methods, procedures and equipment options and design details optimized to meet project objectives for an expedited schedule. The presentation will review specific project examples and discuss production rates, the factors that influence those rates, and how these examples could be applied to other projects. Lessons learned from prior experience regarding what activities can impact your schedule and how they might be avoided will also be discussed.

Presenter:

Matthew Adams, P.E.

Senior Lead Bridge Engineer

Corven Engineering an H&H CompanyMatthew Adams, PE is a Senior Lead Bridge Engineer with Corven Engineering, an H&H Company. Matt has over 20 years’ experience in the design of complex, concrete segmental and post-tensioned bridges specializing in construction engineering. He has performed as the Project Manager / Project Engineer on both precast and cast-in-place segmental concrete bridges, horizontally curved steel box girders bridges, conventional structures, and temporary works and inspection for construction throughout the country, as well as overseas.

Email: madams@hardestyhanover.comPresentation Photos/Graphics:

1) Precast Segment Storage in Casting Yard

1) Precast Segment Storage in Casting Yard 2) Full Span Erected on Falsework Towers

2) Full Span Erected on Falsework Towers -

Exploring Fiber-Reinforced Concrete for Accelerated Bridge Construction Applications Exploring Fiber-Reinforced Concrete for Accelerated Bridge Construction Applications

–

January 26, 2024In this quarterly IBT/ABC-UTC Research Seminar, Travis Thonstad, Ph.D., Principal Investigator; and Carolyn Donohoe, MSCE, EIT, Structural Associate, Moffatt & Nichol, present work related to Fiber-Reinforced Polymer Concrete for Accelerated Bridge Construction Applications conducted at University of Washington.

January 2024 Research Seminar - PDF of presentation slides

Description:

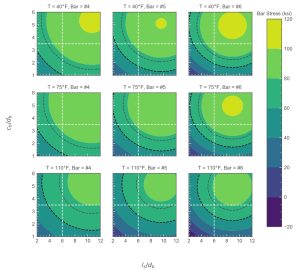

The use of prefabricated superstructure elements in bridge construction reduces on-site construction time, improves work-zone safety, and reduces overall project costs. For prefabricated elements to be used efficiently for accelerated bridge construction (ABC), the precast components, such as deck panels or decked-bulb tees, must be connected quickly on-site, ideally using as little additional material as possible. Polymer concrete has been used successfully as an overlay and repair material in transportation systems for many decades, exhibiting rapid strength gain, low permeability, and higher bond and tension strengths when compared to conventional cementitious concretes. Newer polymer concrete formulations that include fibers have improved mechanical properties and could be suitable for broader use, including structural applications such as closure joints in bridges. This presentation will focus on 1) the bond and mechanical properties of fiber-reinforced polymer concrete (FRPC) at different ages and temperatures and 2) design recommendations for the required splice length of epoxy-coated reinforcement embedded in FRPC materials. The objective of this research is to enable the comparison of FRPC alongside other closure joint materials in future ABC projects.Presenters:

Travis Thonstad, PhD

Assistant Professor, Department of Civil & Environmental Engineering; Associate Director of the Structural Engineering Testing Laboratory

University of Washington in Seattle

Email: thonstat@uw.edu

Presentation Graphics:

Figure 1. Non-contact splice specimen construction sequence

Figure 2. Non-contact splice specimen test setup.

Figure 3. Bar stress as a function of splice length, side cover, bar diameter and temperature.