June 18, 2020 1:00 pm

Paul V. Liles, Jr., P.E., Former State Bridge Engineer, Georgia Department of Transportation; John R. Wolosick, P.E., Senior Advisor, Keller North America; and Tony Sak, P.E., Senior Engineer, Keller North America

Webinar Documents:

Design and Construction of High-Capacity Micropiles in ABC Projects - pdf of presentation

Slide 10: FHWA Micropile Design and Construction Reference Manual, No. FHWA NHI-05-039, December 2005

Slide 38: Video overview of the project including micropile installation (courtesy Georgia DOT)

Slide 38: Time-lapse video of Courtland Street Bridge replacement (courtesy Georgia DOT)

Slide 40: GDOT Special Provision, Section 999, Micropile Foundations

Q&A Session – pdf

News - June 18, 2020 - pdf of presentation

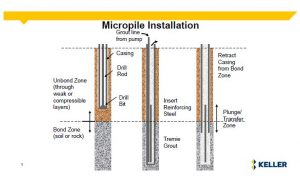

Description: Micropiles are drilled and grouted steel pipe or steel bar piles. They have been in use in the U.S. since the early 1980s. The low headroom (8 feet) required for placement of micropiles allows the installation of new foundations for a replacement bridge while traffic is maintained on the existing bridge, thereby reducing the length of bridge closures for ABC projects. Micropiles are small diameter piles, typically ranging from about 4 ½ inches to less than 12 inches in diameter. They can be installed in challenging ground conditions, such as karstic limestone, boulders, urban fills and high groundwater conditions. Micropiles can also be used where challenging physical constraints such as low headroom, limited access, or vibration sensitive areas exist. Micropiles are installed to carry very high capacities of 100 to over 200 tons service load, even with such small diameters and with very small deflections. The design and construction of micropile foundations in ABC bridge projects, including the 2018 Courtland Street Bridge replacement, with reduced closure requirements will be presented.

Presentation Photos/Graphics:

1) Typical micropile installation procedure