September 19, 2019 1:00 pm

Paul Vaught, P.E., Assistant Bridge Design Administrator, Louisiana Department of Transportation and Development; Craig Finley, P.E., Managing Principal, FINLEY Engineering Group, Inc.; Ivan Liu, P.E., Bridge Engineer, FINLEY Engineering Group, Inc.; and Q&A panel member Bernard Sincavage, P.E., District 04 Eastern Area Engineer, LaDOTD

Webinar Documents:

LaDOTD Introduction - pdf of presentation

Precast Segmental Bridges for the LaDOTD I-49/I-220 Interchange - pdf of presentation

Q&A Session – pdf

News - September 19, 2019 - pdf of presentation

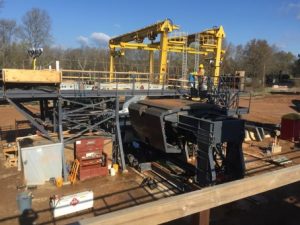

Description: The $138M, I-49/I-220 Interchange in north Shreveport has the first post-tensioned, precast segmental bridges constructed in Louisiana. The three precast segmental bridge ramps consist of 700 precast segments, complex geometry, varying roadway width, straddle piers, cantilever piers and horizontal curves down to a 550-ft radius. Spans vary from 140 ft to 260 ft. During initial project development, the design team defined the project in terms of constructability, considering access, maintenance of traffic, and number of segments to determine the most cost-effective solution. The most economical solution became balanced cantilever erection with ground-based cranes. Design efficiency was maximized using the concept of external continuity post-tensioning with diabolos and a combination of linearly-haunched and constant-depth segments which met aesthetic goals. This webinar will cover how to optimize precasting and erection details for a 700-segment project, casting variable precast segment sections with a common casting machine core form, varying span lengths – common erection method and equipment, optimizing post-tensioning and reinforcing details for consistency and standardization, advantages of external continuity post-tensioning with diabolos, and lessons learned – best practices.

Presentation Photos/Graphics:

5) Completed construction