September 12, 2023 11:00 am

by Michael S. Arens, S.E., P.E., Vice President, Michael Baker International; Michael P. Culmo, P.E., Chief Bridge Engineer, CHA Consulting, Inc.; Peter Graf, P.E., S.E., Executive Vice President, Infrastructure Consulting & Engineering, PLLC; Bijan Khaleghi, Ph.D., P.E., S.E., Principal Structural Engineer, TranTech Engineering; Associate Research Professor and Director of Implementation, ABC-UTC at Florida International University; Amy Leland, P.E., S.E., State Bridge Design Engineer, Bridge & Structures Office, Washington State DOT; Khashayar Nikzad, Ph.D., P.E., Principal Engineer, TranTech Engineering; and Christopher D. White, P.E., Senior Technical Advisor – Structures, Volkert, Inc. – Houston, TX; with Q&A panel members G. J. Schexnayder, P.E., Group Manager – Heavy Construction, Boh Bros. Construction Co., LLC; and Hossein Ghara, P.E., Senior Bridge Design Manager, Volkert, Inc. - Baton Rouge, LA

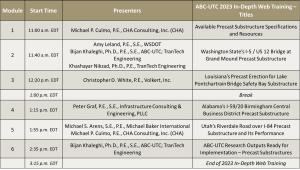

The ABC-UTC 2023 In-Depth Web Training features the latest developments related to precast substructures, and examples of their use. This training is four hours in length and consists of six modules, each a 30-minute presentation followed by a 10-minute Q&A session, with a 15-minute break between Module 3 and Module 4. It starts at 11:00 a.m. Eastern and ends at 3:15 p.m. Eastern.

Description: Prefabricated bridge elements such as precast substructures can provide significant onsite speed for bridge replacement and rehabilitation projects. Precast substructure elements such as pier caps, pier columns, footings, and abutments can be constructed near site or offsite in precast concrete fabrication plants and hauled to the site for immediate erection. The prefabrication can be done prior to bridge closure and concurrent with foundation construction. Although still underutilized, precast substructures are becoming more common as their advantages become better known. This year’s training describes available specifications and design basics, example completed projects, and ABC-UTC research outputs ready for implementation to further improve this important prefabricated bridge element.

Note: Various types of prefabricated substructure elements are listed in the "Keywords for Database Search" for the ABC Project Database.

Presenters

Michael S. Arens, S.E., P.E.

Vice President

Michael Baker International

Phone: 801-352-5981

Email: marens@mbakerintl.com

Mike is a Vice President with Michael Baker International in the Salt Lake City, Utah office. He has been with the firm since 2004. Mike has extensive experience in Accelerated Bridge Construction. He has led the design of multiple ABC projects including the first bridge moved into place using Self Propelled Modular Transporters in the western U.S., Utah’s first transverse bridge slides, and a Single Point Urban Interchange bridge launch over I-15. Mike has worked with multiple DOTs over the years helping to implement new ABC initiatives and projects. He is a graduate of the South Dakota School of Mines & Technology.

Michael P. Culmo, P.E.

Chief Bridge Engineer

CHA Consulting, Inc.

Phone: 860-206-1279

Email: mculmo@chacompanies.com

Mike is a Bridge Engineer with 39 years of experience in bridge and highway design. He has extensive experience in the design of steel, concrete, and prestressed/precast concrete bridges, and has been responsible for managing design teams on new expressway bridges, highway interchanges, and bridge rehabilitation projects. Mike is the author of numerous national publications and manuals on bridges and was the principal author of the 2018 AASHTO LRFD Guide Specifications for Accelerated Bridge Construction. He holds a bachelor’s degree in Civil Engineering and a master’s degree in Structural Engineering, both from the University of Connecticut.

Peter Graf, P.E., S.E.

Executive Vice President

Infrastructure Consulting & Engineering, PLLC

Phone: 919-812-7776

Email:

peter.graf@ice-eng.com

Peter is the Executive Vice President and Technical Director for Infrastructure Consulting & Engineering, a multi-disciplined transportation engineering firm specializing in alternative delivery and value engineering solutions. Over his nearly 30-year career, Peter has designed a broad range of structures including prestressed beam, steel girder, and post-tensioned segmental bridges for both highways and rail. He has led design-build projects valued at over $2 billion located in eight different states and completed numerous value engineering enhancements for ICE’s construction partners. Peter is a proud graduate of Tulane University, a registered Professional Engineer in 14 states, and a registered Structural Engineer in IL and GA.

Bijan Khaleghi, Ph.D., P.E., S.E.

Principal Structural Engineer,

TranTech Engineering;

Associate Research Professor and Director of Implementation,

ABC-UTC at Florida International University

Email: Bkhaleghi@TranTecheng.com

Bkhalegh@fiu.edu

Bijan is the former State Bridge Design Engineer with the Washington State Department of Transportation. He was a member of AASHTO Technical Committees T-8, T-10, and T-20; and member representative of AASHTO at PIARC Road Tunnel Design and Operation. Bijan was the Chair of TRB AKB30, Standing Committee on Concrete Bridges; and member of AKB50, Seismic Design and Performance of Bridges, and AKB60, Tunnels and Underground Structures. He is a member of PCI, ASBI, and PTI. Bijan is recipient of the PCI Robert J. Lyman award, October 2018; PCI Fellow Award, February 2018; ASCE T.Y. Lin Award, March 2014; Charles C. Zollman Award, PCI Journal 2011 and 2013; ASCE SEI T.Y. Lin Award, May 2006; and Martin P. Korn Award, PCI Journal Award 2005.

Amy Leland, P.E., S.E.

State Bridge Design Engineer

Bridge & Structures Office

Washington State DOT

Phone: 360-705-7181

Email: LelandA@wsdot.wa.gov

Amy received her Master of Science in Engineering degree from the University of Washington and is licensed as a Professional Engineer and a Structural Engineer. She has been working in the Washington State Department of Transportation (WSDOT) Bridge Design Office since 1999. Her bridge design experience includes structural analysis and design for reinforced concrete, prestressed concrete, post-tensioned concrete, and steel bridges. Amy was previously the Bridge Seismic and Foundation Specialist for the WSDOT Bridge Design Office. She has participated in establishing policy and overseeing research for WSDOT.

Khashayar Nikzad, Ph.D., P.E.

Principal Engineer

TranTech Engineering

Phone: 425-990-4134

Email: knikzad@trantecheng.com

Khashayar (Kash) has more than 28 years of experience in transportation-related structural analysis and design, and his specialty is in seismic analysis, research and retrofit recommendations. He is regularly involved in all phases of design and construction for transportation projects with bridge structures and has contributed technical papers to well-known civil engineering journals and conferences on the subject matter. Kash has also contributed as a member of PCI’s subcommittee on seismic design of bridges with precast components and to ABC-UTC webinar training in the past.

Christopher D. White, P.E.

Senior Technical Advisor – Structures

Volkert, Inc. – Houston, TX

Phone: 936-777-0610

Email: chris.white@volkert.com

Chris is a Structures Senior Technical Advisor for Volkert, Inc., in Houston, TX. He received his BS degree from the University of Illinois and an MS degree from the University of Texas. His major project resume includes: the Downtown San Antonio “Y” Project in Texas; the Sunshine Skyway Bridge and Roosevelt Bridge in Florida; the “Big Dig” Central Artery/Tunnel Project in Boston; the Kentucky Lakes Arch Bridge; the Lake Pontchartrain Safety Bay Project; and international projects for the Trans Israel Highway and Panama Metro Line 2. Chris is Chair of the PCI Committee on Bridges and serves on the ASBI Technology and Innovation Design Subcommittee and joint PTI/ASBI DC-40 Bridge Design Committee.

Module 1: Available Precast Substructure Specifications and Resources

by Michael P. Culmo, P.E., Chief Bridge Engineer, CHA Consulting, Inc.

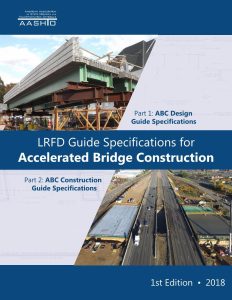

Description: This module focuses on the three major components required to complete a precast substructure design. These include design specifications, construction specifications, and design details. The first two items are covered in the 2018 AASHTO LRFD Guide Specifications for ABC. The third component is design detailing, which is not covered in detail in the Guide Specifications for ABC. Fortunately, the bridge industry has stepped up to develop recommended guide details for precast substructures. The module showcases precast substructure details developed by the Northeast Bridge Technical Committee of the Precast/Prestressed Concrete Institute.

- Module 1 presentation pdf

- Q&A pdf

Module 2: Washington State’s I-5 / US 12 Bridge at Grand Mound Precast Substructure

by Amy Leland, P.E., S.E., State Bridge Design Engineer, Bridge & Structures Office, Washington State Department of Transportation; Bijan Khaleghi, Ph.D., P.E., S.E., Principal Structural Engineer, TranTech Engineering, and Associate Research Professor and Director of Implementation, ABC-UTC; and Khashayar Nikzad, Ph.D., P.E., Principal Engineer, TranTech Engineering

Description: The I-5 / US 12 Bridge at Grand Mound south of Olympia is the Washington State Department of Transportation’s first bridge replacement project to have precast prestressed concrete caps and columns and an all-precast superstructure with seismically-resistant connections. This module focuses on the precast substructure with its cap-to-column grouted duct connections, column-to-column segment grouted duct connections, and column-to-footing socket connections, constructed in 2011. Design and construction details, lessons learned, and performance to date are discussed.

- Module 2 presentation pdf

- Q&A pdf

Module 3: Louisiana's Precast Erection for Lake Pontchartrain Bridge Safety Bay Substructure

by Christopher D. White, P.E., Senior Technical Advisor – Structures, Volkert, Inc. – Houston, TX; with Q&A panel members G. J. Schexnayder, P.E., Group Manager – Heavy Construction, Boh Bros. Construction Co., LLC; and Hossein Ghara, P.E., Senior Bridge Design Manager, Volkert, Inc. - Baton Rouge, LA

Description: Using ABC methods, a $60-million project to install safety bays on America’s longest bridge, the Lake Pontchartrain Causeway in Louisiana, was completed in June 2020. The project introduced six 1008-ft-long x 16-ft-wide safety (pullover) bays at six locations along each of the northbound and southbound structures. The improvements were the product of owner, designer, and contractor collaboration under a Construction-Manager-At-Risk (CMAR) contract. With two lanes of traffic in each direction, no shoulders and over 40,000 vehicles per day, lane closures during construction were not feasible and it was necessary to minimize the duration of construction. Therefore, an all-precast solution was developed – cylinder piles, pile caps and composite girder/slab deck units complete with barrier rails – with only cap-to-existing-cap and cap-to-pile connections being cast-in-place. This module focuses on the precast piles and bent caps, which were erected using barge-mounted equipment to eliminate operations on the deck immediately adjacent to traffic.

- Module 3 presentation pdf

- Q&A pdf

Module 4: Alabama’s I-59/20 Birmingham Central Business District Precast Substructure

by Peter Graf, P.E., S.E., Executive Vice President, Infrastructure Consulting & Engineering, PLLC

Description: The Alabama Department of Transportation needed to replace the aging I-59/20 viaduct through downtown Birmingham with a new 6,000-foot-long structure. The project specifications allowed for a 14-month complete closure of I-59/20 for demo and replacement of the structures. The closure period was enforced with $250,000 per day liquidated damages, but also early completion incentives up to a maximum of $15M. After award of the project to Johnson Bros. / Oscar Renda Joint Venture, Infrastructure Consulting & Engineering, PLLC (ICE) was engaged to re-design the substructure of the bridges from cast-in-place to precast, allowing for the off-site production of the precast elements prior to demo of the existing bridge and rapid erection of the pier columns during the closure period. This ABC method allowed for reduction of the interstate closure period from the allowable 14 months to less than 12 months, opening to traffic in January 2020 and earning the maximum incentive bonus for the construction team. This module focuses on the precast substructure design and construction details and lessons learned.

- Module 4 presentation pdf

- Q&A pdf

Module 5: Utah’s Riverdale Road over I-84 Precast Substructure and Its Performance

by Michael S. Arens, S.E., P.E., Vice President, Michael Baker International; and Michael P. Culmo, P.E., Chief Bridge Engineer, CHA Consulting, Inc.

Description: In 2008, the Riverdale Road / I-84 Single Point Urban Interchange (SPUI) bridge used multiple Accelerated Bridge Construction (ABC) techniques to minimize the impacts to the traveling public during the bridge reconstruction. In addition to saving construction time, these techniques included innovative design and detailing to reduce construction costs and improve construction quality. This module focuses on the precast substructure design and construction details and lessons learned. In addition, the Utah DOT has undertaken a series of inspections of bridges built with ABC methods. The goal is to verify the performance of the bridges over time to ensure that the ABC designs will be durable and long-lasting. The Riverdale Road Bridge has been inspected six times since 2009. The current performance of the bridge, in particular the substructure, is discussed 15 years into service based on the most recent 2023 inspection of this bridge.

- Module 5 presentation pdf

- Q&A pdf

Module 6: ABC-UTC Research Outputs Ready for Implementation – Precast Substructures

by Bijan Khaleghi, Ph.D., P.E., S.E., Principal Structural Engineer, TranTech Engineering, and Associate Research Professor and Director of Implementation, ABC-UTC

Description: This module features ABC-UTC research outputs ready for implementation, with a particular emphasis on precast substructures. The research outputs presented in this module include bridge bent systems with UHPC shell bents and UHPC columns for ABC applications, use of UHPC shells for strengthening bridge columns and deep foundations, innovative connections for permanently cased piles to pier, seismic-resisting connections for concrete-filled tube components, performance evaluation and development of design guidelines for bridge columns with couplers in seismic applications, and design guidelines and constructability of bridge pier systems with UHPC column connections. Also included are integral bridge abutment applications in ABC projects with grouted couplers and innovative connection details. The use of innovative designs, detailing, and materials in bridge bent systems is discussed.